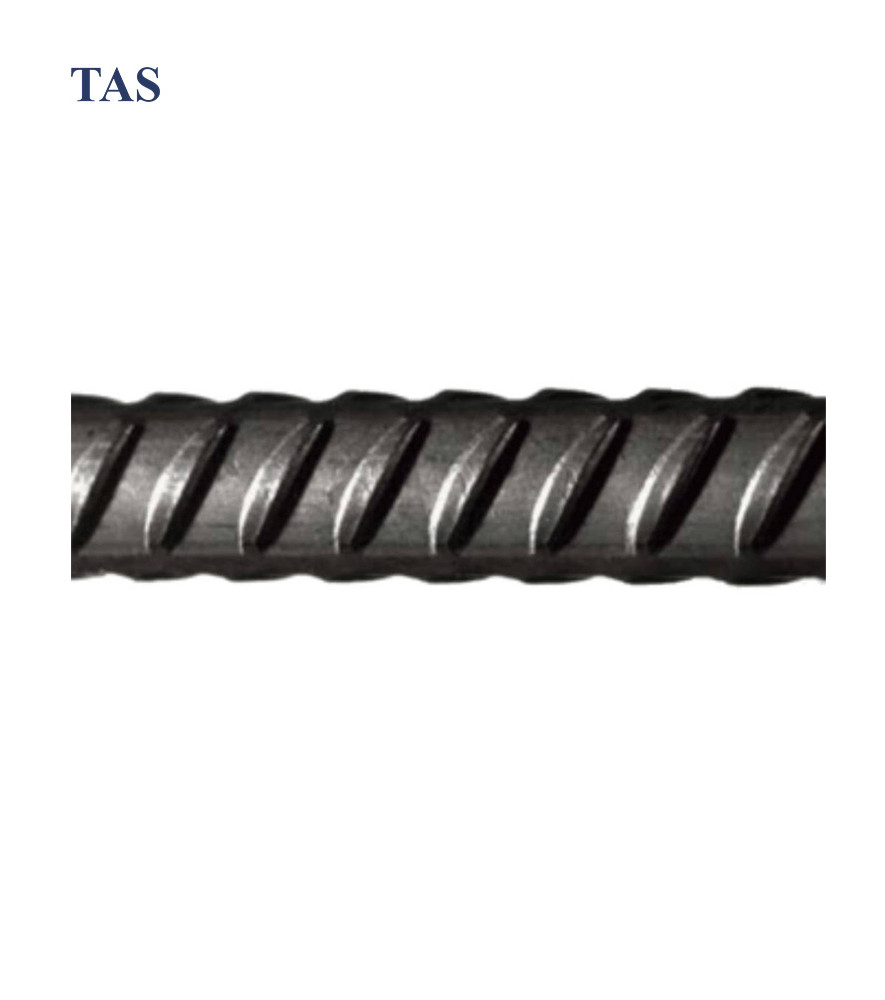

Сold-deformed reinforcing steel B500C for concrete construction reinforcement

DSTU EN 10080:2009

EN 10080; ISO 10544

1006, 1008, 1018 are according to SOU MPP 77.140-236; C4D, С7D, C18D are according to DSTU EN 10016.

Furthermore, applying of reinforcing steel class B500C of rated diameter instead of other classes stated above is performed without conversion of reinforcing and coordination with project organizations that is an important factor of production costs reduction and increasing of reliability of steel reinforcement concrete of constructions objects. For the reinforcement of tensile strength 500, the introduction of intermediate sizes in range from 5,5 to 12 mm allows to save steel up to 16% and to solve the problem of interchangeability of working (estimated) reinforcement of one tensile class with reinforcement of the other class.

Rolled steel according to the current TU U DP 24.3-02070766-002:2015 is intended for reinforcement of steel concrete constructions in standard industrial floors, strip foundations, roadway paving, operated in the open air, in heated and not heated locations.

4,0 - 8,0 mm

Advanced manufacturing technology of reinforcement class B500C implemented on “DNIPROMETYZ TAS” LLC allows to produce steady reinforcement with required characteristics in the range from 4,0 to 8,0mm, with any intermediate diameter.

|

Nominal diameter, dн, mm |

Rated cross-section area FH, mm2 |

Rated weight 1m length m, kg |

Permitted weight deviations 1m length % % |

|

4,0 |

12,60 |

0,099 |

± 4,5 |

|

5,0 |

19,63 |

0,154 |

|

|

6,0 |

28,27 |

0,222 |

|

|

7,0 |

38,50 |

0,303 |

|

|

8,0 |

50,26 |

0,395 |

|

| Note : Weight of 1 running meter is calculated proceeding from rated steel density (7,85g/cm3) | |||

The reinforcement is supplied with accurate rolling marking – stamping a trademark “DM” of the manufacturer PrJSC “Dneprometiz” on one side of the profile.

|

Profile number (nominal diameter) mm |

Height of lug h, mm |

Pitch of lug с, mm |

Relative pitch of lug с/b, not less |

Total interval between ends of transverse ribs ∑eוֹ, mm, max |

Relative area of profile’s transverse ribs deformation fR, not less, mm |

Ovality of rolling, mm, max |

|

4,0 |

0,20-0,40 |

1,6-4,0 |

3 |

3,14 |

0,036 |

0,5 |

|

5,0 |

0,25-0,50 |

2,0-5,0 |

3,93 |

0,039 |

0,5 |

|

|

6,0 |

0,30-0,60 |

2,4-6,0 |

4,71 |

0,039 |

1,0 |

|

|

7,0 |

0,35-0,70 |

2,8-7,0 |

5,50 |

0,045 |

1,0 |

|

|

8,0 |

0,40-0,80 |

3,2-8,0 |

6,28 |

0,045 |

1,0 |

|

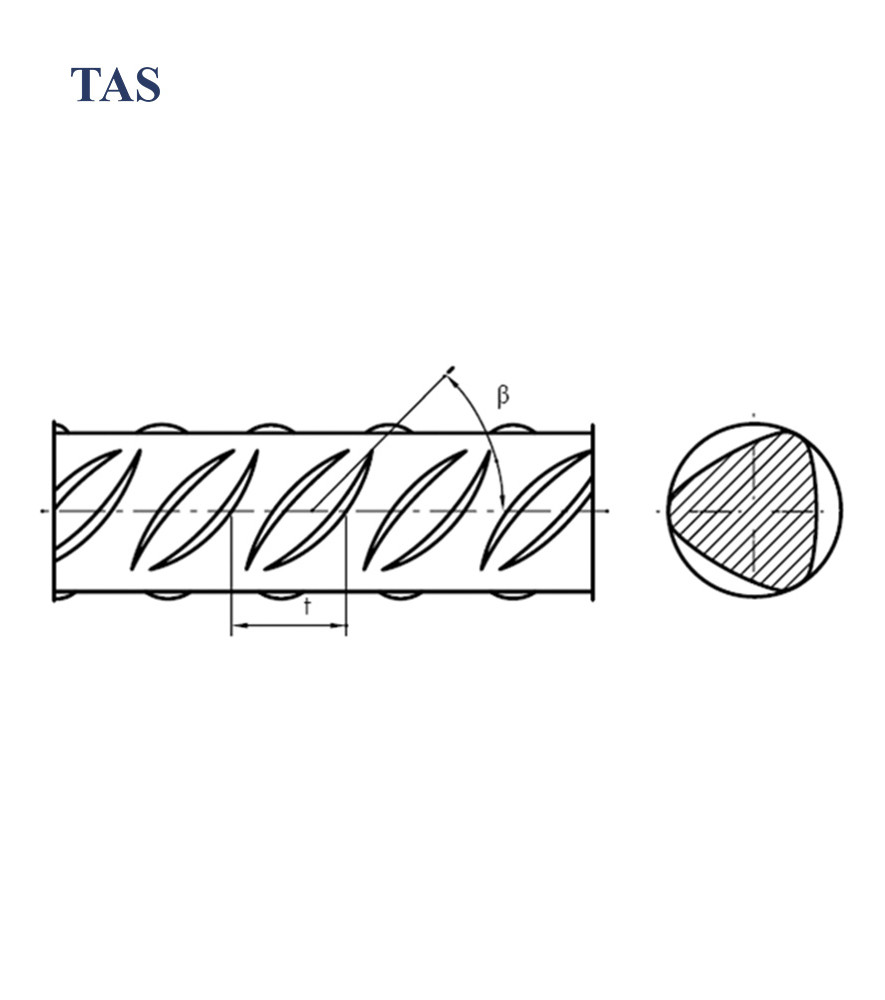

| Slope angle of transverse rib β = (35-60)°.Slope angle of lateral surface of transverse rib α=(45-60)° | ||||||

|

Description and properties |

Value index |

Allowed probability of assurance |

|

Not less |

||

|

Conventional yield strength , σ0,2, МPa |

500 |

0,90 |

|

Tensile strength σв, МPа |

550 |

0,95 |

|

Ratio σв/σ0,2 |

1,05 |

0,95 |

|

Total relative elongation at maximum stress, Аgt, % |

2,5 |

0,90 |

|

Quantity of bends on 180 degrees round arbor of diam.3dн: -for rolling of rated diameter 4,0-4,5mm -for rolling of rated diameter 5,0-5,5mm |

4 5 |

- |

|

Rolling of rated diameter 6,0-8,0 mm should pass bending test on angles 180 and 90 degrees respectively round arbor of diameter equal 3dн. |

Absence of fractures and cracks |

- |

|

Type of shipment |

Weight, kg |

Inner diameter |

Outer diameter |

Height |

|

Heavy-weight coil |

550±50 950±50 1950±100 2950±100 |

650±10 450±10 500±10 620±10 |

830±20 830±20 960±20 1050±20 |

440±20 440±20 650±20 840±20 |

When forming a transport package in bars, each package is tied tightly in three places by wire rod of diameter 5,5 - 8,0mm. On each coil or package at least two clamps are fasten for fixing the strops of crane mechanisms providing the mechanized loading and unloading of the goods.

Coils of weight up to 3000 kg

Bars length (L) from 1,0 up to 6,0 m., package of weight up to 300 kg.