Low-carbon general purpose steel wire, heat-treated

For the manufacture of nails, bindings, fences, wicker nets.

0,5 - 13,00 mm

St1, St2, St3 of all degrees of deoxidization are according to DSTU 2770-94;

1006, 1008, 1010, 1011, 1012, 1013, 1015, 1016, 1017, 1018, 1020 are according to SOU MPP 77.140-236;

С4D, С7D, С9D, С10D, С12D, С15D, С18D, C20D are according to DSTU EN 10016.

By the additional agreement with the Supplier the production of the wire with intermediate diameters is possible.

At the customer’s request it is possible to produce the wire with more strict requirements regarding the geometry and tensile strength, without oxide scale in the "light annealing" mode.

The production of oiled wire is possible.

| Nominal diameter, mm | Wire diameter tolerance, mm |

Tensile strength, N/mm2(kg/mm2) |

Relative elongation, %, not less | Type of shipment – coils weight, kg |

| 0,5 – 0,75 | -0,04 |

290-490 (30-50) |

15 | small coils of free winding of 20-40 |

| 0,8 – 1,0 | -0,05 | 15 |

small coils of free winding of 25-80; heavy-weight coils of 550±50; heavy-weight coils of 950±50 of conic winding; coils of "Rosette" type up to 300 |

|

| 1,1 – 1,2 | -0,06 | 15 | ||

| 1,3 – 1,5 | -0,10 | 15 | ||

| 1,6 – 2,0 | -0,10 | 15 |

small coils of free winding of 30-80; 100 ±10; heavy-weight coils of 950±50; 1950±100 coils of "Rosette" type up to 800; coils of "Brehmen rings" type of 20-40 |

|

| 2,2 – 2,5 | -0,12 | 15 | ||

| 2,8 – 3,2 | -0,12 | 15 | ||

| 3,5 – 4,5 | -0,16 | 15 | ||

| 5,0 – 6,0 | -0,16 | 20 | ||

| 7,0 – 10,0 | -0,20 | 20 | heavy-weight coils of 300-400; 950±50; 1950±100 | |

| 11,0 – 13,0 | -0,20 | 20 | coils of free winding of 300-500 |

| Admissible tolerances on diameter of wire, mm | The range of diameters precision class, mm | ||

| Т1 | Т2 | Т3 | |

| ±0,012 | – | – | 0,25≤ d <0,33 |

| ±0,015 | – | 0,25≤ d <0,31 | 0,33≤ d <0,52 |

| ±0,020 | – | 0,31≤ d <0,55 | 0,52≤ d <0,91 |

| ±0,025 | 0,30≤ d <0,52 | 0,55≤ d <0,86 | 0,91≤ d <1,42 |

| ±0,030 | 0,52≤ d <0,74 | 0,86≤ d <1,24 | 1,42≤ d <2,05 |

| ±0,035 | 0,74≤ d <1,01 | 1,24≤ d <1,69 | 2,05≤ d <2,78 |

| ±0,040 | 1,01≤ d <1,31 | 1,69≤ d <2,20 | 2,78≤ d <3,63 |

| ±0,045 | 1,31≤ d <1,66 | 2,20≤ d <2,78 | 3,63≤ d <,4,60 |

| ±0,050 | 1,66≤ d <2,05 | 2,78≤ d <3,43 | 4,60≤ d <5,67 |

| ±0,060 | 2,05≤ d <2,94 | 3,43≤ d <4,94 | 5,67≤ d <8,17 |

| ±0,070 | 2,94≤ d <4,01 | 4,94≤ d <6,73 | 8,17≤ d ≤11,12 |

| ±0,080 | 4,01≤ d <5,23 | 6,73≤ d <8,78 | 11,12≤ d ≤13,00 |

| ±0,090 | 5,23≤ d <6,62 | 8,78≤ d ≤11,12 | – |

| ±0,100 | 6,62≤ d <8,17 | 11,12≤ d ≤13,00 | – |

| ±0,120 | 8,17≤ d ≤11,76 | – | – |

| ±0,140 | 11,76≤ d ≤13,00 | – | – |

| The range of diameters precision class I, mm | Admissible tolerances on diameter of wire, mm |

| 0,25≤ d <0,28 | ±0,010 |

| 0,28≤ d <0,37 | ±0,015 |

| 0,37≤ d <0,63 | ±0,020 |

| 0,63≤ d <1,10 | ±0,025 |

| 1,10≤ d <1,30 | ±0,03 |

| 1,30≤ d <2,20 | ±0,05 |

| 2,20≤ d <3,50 | ±0,06 |

| 3,50≤ d <6,30 | ±0,08 |

| 6,30≤ d ≤10,00 | ±0,10 |

|

Wire diameter, mm |

Coil weight, kg |

Outer diameter of coil, mm |

Inner diameter of coil, mm |

Height, mm |

Quantity of coils in package, pcs. |

Outer diameter of package, mm |

Inner diameter of package, mm |

Height of package, mm |

|

0,5 – 1,5 |

25 | 440 ±10 | 250 ±10 | 100 ±10 | 8 |

460 ±10 |

220 ±10 |

520 ±20 |

|

440 ±10* |

240 ±10* |

700 ±30* |

||||||

| 50 | 450 ±10 | 230 ±10 |

140 ±10 |

6 |

470 ±20 |

200 ±20 |

430 ±30 |

|

|

450 ±10* |

230 ±10* |

610 ±20* |

||||||

|

80 |

460 ±20 |

220 ±20 |

200 ±20 |

5 |

470 ±20 |

200 ±20 |

480 ±30 |

|

|

450 ±10* |

230 ±10* |

780 ±40* |

||||||

|

1,0 – 1,5 |

550 ± 50 |

710 ±10 |

450 |

420 ±10 |

||||

|

0,6 – 1,5 |

950±50 are of conic winding |

top 700 ±10 |

355 |

580 |

||||

|

base 745 ±10 |

||||||||

|

1,6 – 2,8 |

50 |

620 ±20 |

470 ±20 |

80 ±20 |

8 |

640 ±20 |

440 ±20 |

480 ±60 |

|

630 ±20* |

410 ±20* |

850 ±30* |

||||||

|

80 |

650 ±20 |

460 ±20 |

130±20 |

5 |

700 ±20 |

410 ±20 |

460 ±60 |

|

|

660 ±20* |

420 ±20* |

700 ±60* |

||||||

|

100 ± 10 |

660 ± 20 |

460 ±20 |

150 ±20 |

5 |

700 ±20 |

410 ±20 |

460 ±60 |

|

|

660 ±20* |

420 ±20* |

700 ±60* |

||||||

|

3,0 – 6,0 |

50 |

620 ±20 |

470 ±20 |

90 ±20 |

8 |

640 ±20 |

440 ±20 | 510 ±60 |

|

630 ±20* |

410 ±20* |

870 ±30* |

||||||

|

80 |

650 ±20 |

460 ±20 |

140 ±20 |

5 |

700 ±20 |

410 ±20 |

510 ±60 |

|

|

660 ±20* |

420 ±20* |

720 ±60* |

||||||

|

100 ± 10 |

660 ±20 |

460 ±20 |

160 ±20 |

5 |

700 ±20 |

410 ±20 |

510 ±60 |

|

|

660 ±20* |

420 ±20* |

720 ±60* |

||||||

|

1,6 – 6,0 |

950 ± 100 |

830 ± 20 |

450 ± 10 |

440 ± 20 |

||||

|

2,4 – 10,0 |

1950±100 |

960±20 |

500±10 |

650±20 |

||||

|

2950±100 |

1050±20 |

620±10 |

840±20 |

|||||

|

5,5 – 8,0 |

80-300 |

750 |

500 |

80-300 |

||||

|

5,5 – 10,0 |

80-300 |

850 |

600 |

80-300 |

||||

|

6,0 – 13,0 |

500 |

1100±100 |

520 ±20 |

400 |

|

Parameter |

Rosette Size |

||

| Wire diameter, mm |

0,8 – 1,5 |

1,6 – 4,0 |

|

| Weight, kg |

150±10 |

500±10 |

1000±10 |

| Outer Diameter, mm |

450 ±10 |

810 ±10 |

810 ±20 |

| Inner diameter, mm |

225 ±20 |

370 ±10 |

370 ±10 |

| Height, mm |

480 ±20 |

430 ±20 |

900 ±20 |

|

Wire diameter, mm |

Coil weight, kg |

Outer diameter of coil, mm |

Inner diameter of coil, mm |

Height, mm |

Inner diameter of spool, mm |

|

0,25-0,55 |

до 20 |

250 |

160 |

200 |

36 |

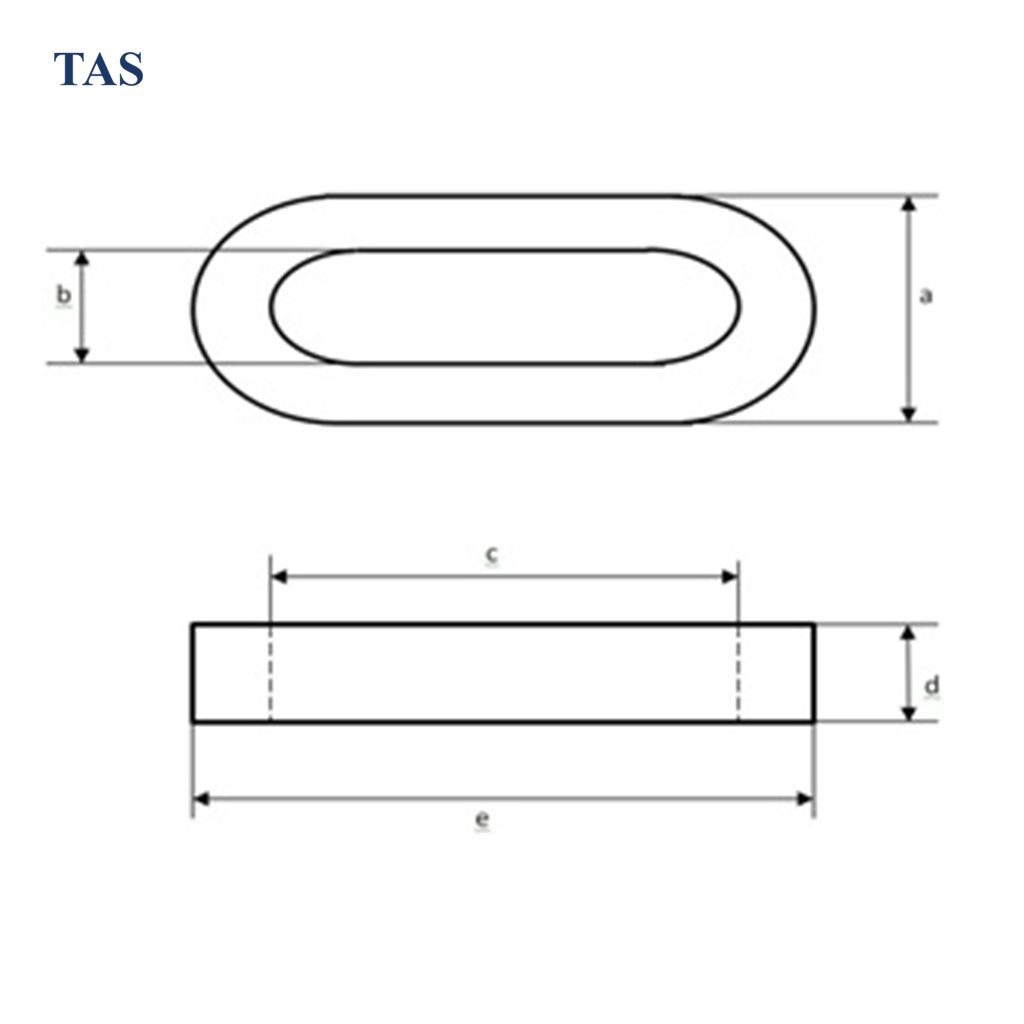

Production of heat-treated wire is possible in coils of rectangular section – “Brehmen rings”

with the following technical requirements:

- diameters from 2,00 up to 5,00 mm; wire oiled/not oiled;

- tensile strength 300-400 N/mm2;

- the production of oiled wire is possible.

Overall dimensions of coils “Brehmen rings”:

|

Coil weight, kg |

Inner diameter, mm |

Outer diameter, mm |

Height, mm |

|

20 |

100 |

250 |

100 |

|

30 |

210 |

310 |

150+2 |

|

40 |

210 |

330+5 |

150+2 |

Production of heat-treated wire is possible in coils with a special form winding of weight 200 grams

with the following technical requirements:

- diameters from 1,2 mm; 1,4 mm; 1,6 mm; wire not oiled;

- tensile strength 300-490 N/mm2;

Sizes acc. to drawing in mm:

|

a |

b |

c |

d |

e |

|

44-52 |

17-20 |

39-43 |

23-26 |

65-70 |

Type of packaging: plastic buckets of 20 kg (100 coils)

Type of shipment: on pallet, net weight 720 kg (36 buckets)

|

Type of shipment |

Weight, kg |

Material or combination of materials for packing |

|

Plastic spools К-250А |

up to 20 |

Without additional packing |

|

Stretch |

||

|

Coil |

20-100 |

Without additional packing |

|

Stretch (for wire diam (0,5-0,8) mm |

||

|

polyethylene film |

||

|

inhibited film |

||

|

Package coils Heavy-weight coil Heavy-weight coil (conical winding) Heavy-weight coil “Rosette” |

180-500 550±50 950±50 950±50 1950±100 up to 1000 |

Without additional packing |

|

Stretch (for heavy-weight coils of conical winding |

||

|

polyethylene film |

||

|

inhibited film |

||

|

polypropylene sleeve |

||

|

inhibited film + polypropylene sleeve |

||

|

polyethylene film + polypropylene sleeve |

||

|

two-layer sleeve (polypropylene with inhibited paper) |