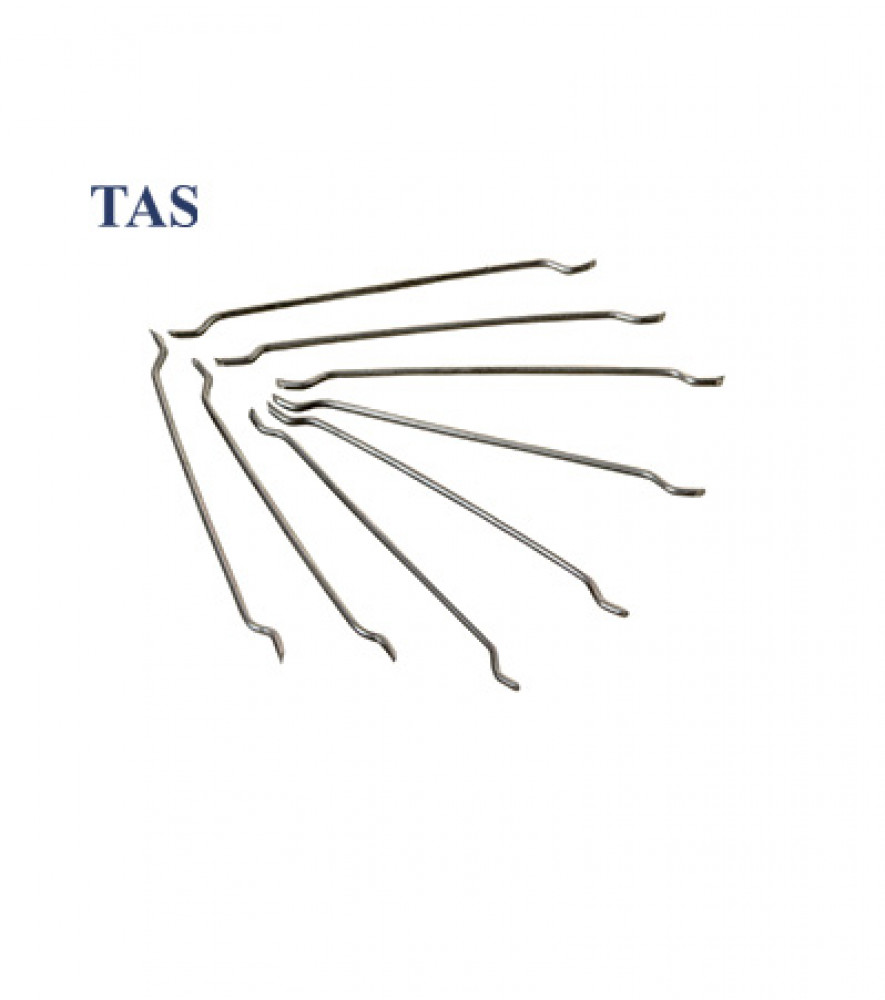

Steel wire fiber for concrete reinforcement

Steel fiber is used as a disperse material for the reinforcing of steel fiber concrete and torkrete concrete.

Quality parameters of steel fiber correspond to the requirements of ASTM A 820 (to a fiber of type I)

0,6 — 1,0 mm

32 — 60 mm

St1, St2 are according to DSTU 2770-94;

1006, 1010, 1012, 1018, 1020 are according to SOU MPP 77.140-236

EN 14889-1:2006; TI 283-MT.PR-71-2016, TI 283-MT.PR-70-2017

Deformed with hooked ends (DZ). Without coating

Deformed with hooked ends (DZ). Without coating Steel fiber is certified by the Institution that fulfills the Certification of the building products «STATYBOS PRODUKCIJOS SERTIFIKAVIMO CENTRAS» regarding the correspondence to EN 14889-1:2006.

|

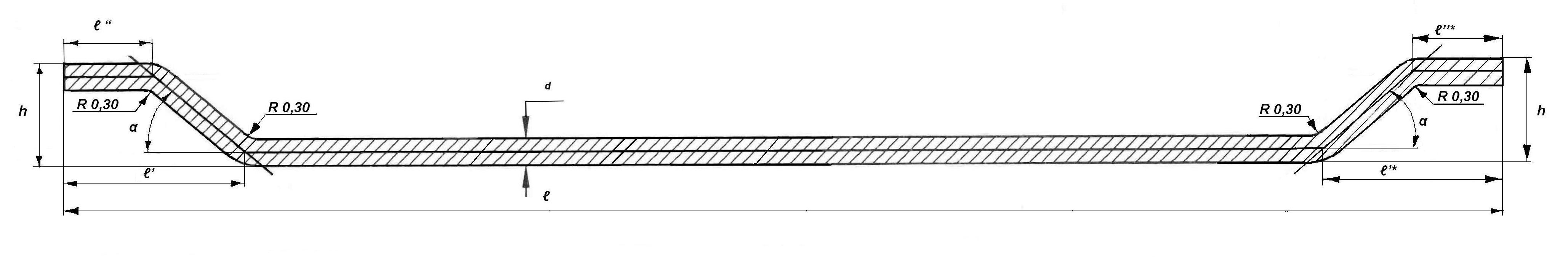

d – fiber diameter, mm |

l – fiber length, mm |

λ – value (ratio l/d) |

h – hook height, mm |

ℓ´, ℓ´*– length of hooked ends, mm |

ℓ”, ℓ”*– anchor length, mm |

α’, α″– bend angle, |

Quantity in 1kg, pieces |

|

0,6 ± 0,03 |

32,0 ± 1,6 |

53 ± 4 |

2,4 ± 0,5 |

5,0 ± 1,9 |

мин. 1 |

45 ± 10 |

~ 14 075 |

|

0,75 ± 0,03 |

50,0 ± 2,0 |

67 ± 5 |

3,1 ± 0,3 |

5,0 ± 1,9 |

мин. 1 |

45 ± 10 |

~ 5 586 |

|

0,75 ± 0,03 |

52,0 ± 2,0 |

69 ± 4 |

3,1 ± 0,3 |

5,0 ± 1,9 |

мин. 1 |

45 ± 10 |

~ 5 348 |

|

0,8 ± 0,04 |

50,0 ± 2,0 |

63 ± 4 |

2,9 ± 0,5 |

5,0 ± 1,0 |

мин. 1 |

45 ± 10 |

~ 4 894 |

|

0,8 ± 0,04 |

60,0 ± 3,0 |

75 ± 5 |

3,0 ± 0,5 |

5,0 ± 1,0 |

мин. 1 |

45 ± 10 |

~ 4105 |

|

0,9 ± 0,05 |

60,0 ± 3,0 |

66 ± 5 |

3,0 ± 0,5 |

5,0 ± 1,0 |

мин. 1 |

45 ± 10 |

~ 3225 |

|

1,0 ± 0,05 |

50,0 ± 2,0 |

50 ± 3 |

3,1 ± 0,5 |

5,0 ± 1,0 |

мин. 1 |

45 ± 10 |

~ 3 132 |

|

1,0 ± 0,05 |

60,0 ± 3,0 |

60 ± 4 |

3,1 ± 0,5 |

5,0 ± 1,0 |

мин. 1 |

45 ± 10 |

~ 2 629 |

| Steel fiber size | Rm – average value of the tensile strength of the wire, N/mm2 | Steel fiber consistence, kg per 1m3 of concrete, min | E –modulus of elasticity, MPa | Effect on concrete Consistency, seconds acc. to Vebe | Effect on concrete hardness |

|

60/32 |

1300 |

20 |

200 000 |

7 |

The residual flexural strength of the concrete is 1,5 N/mm2 by CMOD = 0,5 mm (the width of the crack opening) and 1 N/mm2 by CMOD = 3,5 mm |

|

60/32 |

1550 |

15 |

6 |

||

|

75/50 |

1200 |

25 |

6 |

||

|

75/52 |

1500 |

20 |

8 |

||

|

80/50 |

1200 |

25 |

8 |

||

|

80/50 |

1500 |

20 |

7 |

||

|

80/60 |

1200 |

25 |

5 |

||

|

80/60 |

1500 |

20 |

4 |

||

|

90/60 |

1150 |

25 |

5 |

||

|

90/60 |

1500 |

20 |

4 |

||

|

1/50 |

1150 |

30 |

8 |

||

|

1/50 |

1500 |

20 |

6 |

||

|

1/60 |

1150 |

20 |

6 |

||

|

1/60 |

1500 |

25 |

6 |

- Cardboard boxes of net weight 25 kg, packed on the pallet, net weight 1125 kg

- Polypropylene big-bag on the pallet of net weight up to 1000 kg